Sales and operations planning is a critical integrated business planning process that strategically aligns sales, marketing, operations, and finance. By balancing supply and demand, it enables organizations to enhance forecast accuracy and optimize inventory planning, business growth, and profitability.

Effective S&OP facilitates cross-functional coordination between departments that have traditionally operated in silos. Instead of disconnected plans, S&OP creates unified company-wide plans (integrated planning) that translate top-level goals into day-to-day operations (strategic to tactical planning).

With data-driven integrated plans, organizations can pursue opportunities and mitigate risks with confidence. This article will explore the elements of a world-class sales and operations planning process and how it powers business success through balanced supply chain planning. Aligning supply, demand, collaboration, and resources is at the heart of S&OP.

What is Sales and Operations Planning?

Sales and operations planning (S&OP) is a formal business management process that helps companies optimize supply and demand. It accomplishes this by linking high-level strategic plans (strategic planning) to tactical day-to-day operations (tactical planning).

The key goals of S&OP include:

- Balancing supply and demand by aligning production, procurement, and inventory plans with sales forecasts. This enhances customer service levels.

- Enabling integrated business planning by synthesizing plans across sales, marketing, operations, finance, and other departments.

- Promoting cross-functional collaboration between teams to create unity.

- Providing the executive team with visibility into integrated plans and metrics for data-driven steering of the business.

The S&OP process gives organizations the agility to respond to changing market conditions and supply chain events. Rather than operating in departmental silos, S&OP breaks down barriers and drives a coordinated approach.

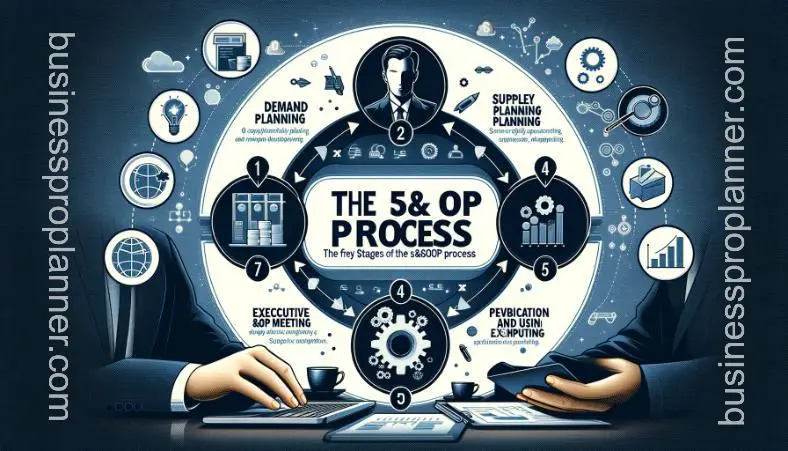

The 5 Stages of the S&OP Process

An effective sales and operations planning (S&OP) process follows five key stages:

Demand Planning

The first stage in S&OP is creating demand forecasts to estimate expected sales and customer demand (sales forecast, demand forecast). Historical sales data provide the baseline, which is then adjusted for seasonality, promotions, and external factors like new product launches, competitor actions, and economic conditions. Statistical forecasting techniques help enhance forecast accuracy.

Supply Planning

Next, the supply planning process determines the production, sourcing, inventory, and resource levels required to meet the demand forecast. Supply planners assess constraints related to production capacity, raw material availability, inventory policies, and other factors to create a feasible supply plan.

Pre-S&OP Meeting

In this step, the demand plan and supply plan are reconciled by sales and operations teams in a pre-S&OP meeting. They identify mismatches between demand and supply and adjust the plans accordingly to align supply and demand. Collaboration between planners enables an integrated plan.

Executive S&OP Meeting

The integrated demand and supply plans are then reviewed in an executive S&OP meeting including senior leaders. The executive team gains visibility into sales projections, supply capabilities, and resource requirements. They review key S&OP metrics and ensure alignment with financial plans and business strategy.

Publication and Execution

Finally, the demand and supply plans are finalized and communicated to relevant departments. The production plan details production schedules and procurement needs. The sales plan sets quotas and revenue targets. Budgets, hiring plans, and inventory policies are realigned based on the integrated S&OP plans.

Best Practices for Effective S&OP

Implementing the following best practices can drive S&OP success:

- Cross-Functional Participation: The S&OP team should include representatives from sales, marketing, operations, finance, product management, and other relevant departments.

- Data-Driven Forecasts: Statistical forecasting and demand sensing technology enable data-driven projections rather than gut feel.

- Scenario Planning: Evaluate multiple scenarios and contingency plans to account for uncertainties in demand or supply.

- Executive Sponsorship: Senior management must actively sponsor and participate in the S&OP process.

- Aligned Metrics and Incentives: Departmental incentives should tie into company-wide S&OP goals versus local optimization.

- Rapid Response to Changes: Reevaluate and update plans rapidly in response to demand or supply changes rather than rigid schedules.

- Specialized Software: Purpose-built S&OP software like SAP seamlessly integrates diverse business data, enabling precise forecasting and effective resource management. Additionally, it enhances interdepartmental collaboration and supply chain transparency, facilitating synchronized planning efforts.

- Ongoing S&OP Education: Continual training and workshops ensure organizational alignment and capability.

Benefits of Sales and Operations Planning

An effective effective S&OP process offers significant benefits:

- Improved Forecast Accuracy in Supply Chain Management: Data-driven forecasts significantly outperform guesswork. This accuracy is pivotal in supply chain management, providing a solid foundation for reliable planning and decision-making.

- Optimized Inventory Through Effective Product Planning: By aligning inventory with production plans, businesses adept in product planning can effectively reduce surplus stock and prevent shortages. This optimization is crucial for maintaining operational balance.

- Enhanced Customer Service via Focused Product Development: Implementing demand-driven plans in product development leads to better fill rates and timely delivery. Such strategic approaches ensure that customer service standards are consistently met and exceeded.

- Increased Productivity in Operations Management: Streamlining processes to remove redundancies is a key aspect of operations management. This focus on efficiency not only eliminates resource wastage but also significantly boosts overall productivity.

- Mitigated Supply-Demand Risk through Resource Planning: Early identification and proactive realignment of supply and demand mismatches are essential in resource planning. This proactive approach helps in effectively mitigating potential risks.

- Strategic Alignment with Executive Involvement: Executive involvement in sales and operations planning ensures that operational plans are in sync with the corporate strategy. This alignment is a vital part of the integrated business management process.

- Data-Driven Decisions for Enhanced S&OP Outcomes: Utilizing reliable S&OP data for critical decision-making supports sales and operations planning best practices. Such data-driven approaches are key to driving profitability and growth within an organization.

Challenges and Solutions in Sales and Operations Planning

Common obstacles in S&OP and how to overcome them

- Lack of executive commitment and sponsorship

- Departmental silos and lack of cross-functional coordination

- Inconsistent and unreliable data inputs

- Resistance to change and lack of education

Solutions:

- Obtain strong executive leadership and sponsorship

- Implement cross-functional S&OP teams

- Invest in data quality and forecasting capabilities

- Provide extensive training and education on S&OP

- Demonstrate quick wins and benefits to gain buy-in

Case studies or examples of successful S&OP implementation

Companies such as Coca-Cola, Eli Lilly, Lenovo, and others have successfully implemented S&OP, leading to significant benefits. One automotive company achieved 20% forecast accuracy improvements and millions in cost savings through inventory optimization. Another manufacturer attributes enhanced customer service levels to S&OP balancing supply and demand. Critical success factors include executive leadership, process rigor, collaboration tools, and embedding S&OP into culture and incentives.

Metrics and Performance Measurement in S&OP

Key metrics for assessing S&OP effectiveness

- Forecast accuracy

- Inventory turns

- Perfect order fulfillment

- Operating expenses

- Profitability targets

- Labor utilization

- Customer service levels

How to track and improve S&OP performance

- Leverage planning software to capture key S&OP metrics

- Perform regular plan reviews and variance analysis

- Root cause analysis of misses to continuously improve

- Refine forecast models and data inputs

- Optimization and simulations to determine the best options

The Future of Sales and Operations Planning

Evolving trends in S&OP

- Artificial intelligence and machine learning for smarter forecasting

- Increased scenario modeling and simulations

- Real-time visibility and monitoring with digital tools

- Extension of S&OP across supply chain partners

- Predictive, forward-looking insights vs. reactive focus

The impact of digital transformation on S&OP

Digital platforms allow greater collaboration, improved data availability, and advanced analytics capabilities. This facilitates detailed demand sensing, rapid forecast updates, and hyper-connected value chains. S&OP is transitioning from reactive and backward-looking to predictive and forward-looking with proactive planning vs. response.

Conclusion

In wrapping, Sales and Operations Planning (S&OP) stands as a pivotal process in driving business success. It’s the backbone that aligns every cog in the company’s machinery – from sales and marketing to the intricate operational planning process. Utilizing SAP-integrated business planning, businesses can navigate through the steps of the S&OP process with clarity and precision.

This process not only brings departments together but also paves the way for effective supply chain management. By integrating supply and demand plans, it anticipates future sales and molds strategies accordingly. The benefits of S&OP are clear: it enhances supply chain performance, ensures smoother collaboration between sales and operations teams, and addresses the challenges of sales and operations planning head-on.

At its core, the purpose of S&OP is to foster growth and profitability. It’s a journey that involves everyone in the organization, involved in the process from start to finish. The planning cycle in S&OP is not just a set of steps, it’s a strategic route that enables effective supply chain management and drives the company toward its goals. Remember, operations planning is not just a process – it’s the heartbeat of a thriving business.